ABRASION GUARDS

Protection from the protective cover

first, a caveat

This project requires sewing, and although I have done some from time to time on straps and such, and more recently, the rework of the truck’s dinette upholstery, it’s definitely not my specialty. Add to that the fact that the only sewing machine I have to work with was made in the 1930s. So trust me when I say, you’re not going to see something that you’d find in a Bentley. What’s important for this project is actually the non-visual part. That which lies against the paint and polycarbonate that we need to protect… the inside of the sleeves.

Solving a dilema

One of the biggest challenges of carrying a motorcycle on the back of the truck is keeping it clean from all the road grime deposited on it from the suction created at the back of a moving box.

Even bungee cords couldn’t prevent the cover from moving, and keep it from damaging the paint underneath.

Typically, this would be done by putting a motorcycle cover over the bike to reduce the debris that would otherwise collect on the bike surfaces. It sounds like the right solution except for one thing, abrasion. You see, as the vehicle moves down the road, the motion of the truck is transferred to the bike, and this motion causes the bike cover to billow, then relax, then billow again. This causes the cover to act as a bellows, and each successive billowing sucks in air, and any grit floating in it. The grit lands on the bike, and the relaxing cover then rubs on the bike’s grit covered surfaces. Over time, the result is like having sand paper continually rub on the paint, plastic and or windshield, and cause considerable damage. What makes things worse is that most motorcycle covers are made from thin fabric which is easily blown around by the wind, and this exacerbates the problem.

Fortunate Developments

After considerable time spent looking for some kind of a solution that would save us from having to construct a solid box of sorts on the back of the truck, I came across a bike cover made specifically for large adventure bikes with top boxes and panniers.

Made by Touratech in Germany, this cover is a step above the regular run of the mill covers. Made of a very heavy vinyl type fabric with a soft interior surface, this cover weights over 8 pounds, and is large enough to reach the deck of our lift platform when there are no panniers attached. This allowed us to attach snaps to the deck and the cover so the environment inside can be sealed off. That goes a long way to preventing grime infiltration, and therefore reduces abrasion.

Despite the improvement of the Touratech cover over the others we’ve used, it still has the problem of moving about with the wind. So to reduce this, we added some velcro straps, a zipper and some velcro to “flaps” that the bagginess of the cover could create when it was folded over onto itself.

It was a pain of a job because of the bulky nature of the cover, and the non-slip nature of the vinyl exterior. That alone made pushing it through the sewing machine difficult. But with perseverance, we got the work completed.

To help, we also decided to eliminate the live suspension on the bike while it’s on the lift. We noticed by watching the rear camera image of the bike on the lift, that it’s pretty much motionless while we are driving. This meant that we didn’t need to worry about shocks to the lift when hitting bumps on the road, which is why we originally went with a sprung suspension on the bike. So we made a chock to go under the frame of the bike where the centre stand is, and then use four ratchet straps to pull the bike down about 1.5” (38mm) until it touches the chock. Now there will be no up and down movement by the bike that causes the bellows effect with the cover.

Extra Level of Protection

Although the new bike cover has great possibilities, there is still a worry. Unlike the typical metal top boxes of most adventure bikes, ours is a bit more upscale in its finish, with nice upholstery and a high gloss painted finish that matches the other paint on the BMW R1250 GSA. Along with that, we added a larger windscreen that came from Wunderlich, Germany. Both of these items will be feeling the weight of the cover hanging on them, and we just don’t want to take a chance that the cover itself might scratch or abrade the surfaces. So to alleviate that worry, we decided to make some form fitted sleeves that will act as a second skin.

Windshield Sleeve

The first piece, since it was the easiest, was the windshield sleeve. The 5mm thick polycarbonate plastic that the windshield is made from, although literally bullet proof when used in a thicker form, is easy to scratch. Much more so than acrylic. Since it’s something that one looks through, it’s the first thing on which scratches would be noticed.

The fabric we found has a nice soft pile on the backside of it. This should work well to prevent scratches on the paint and plastic.

The process started with finding the right fabric. It needed to be impermeable to dust on the outside, but soft on the inside. Luckily we found a leatherette material that has a soft fuzzy underside. We couldn’t get it in any colour other than a light tan colour, but since it’s only going to be used under the motorcycle cover and never really seen, the colour wasn’t that important.

With the material chosen, the first step was to lay it over the windshield and trace the shape on the underside. From there it was a matter of measuring and finishing the layout on the inside of the fabric. Then cut and sew.

Top Box Sleeve

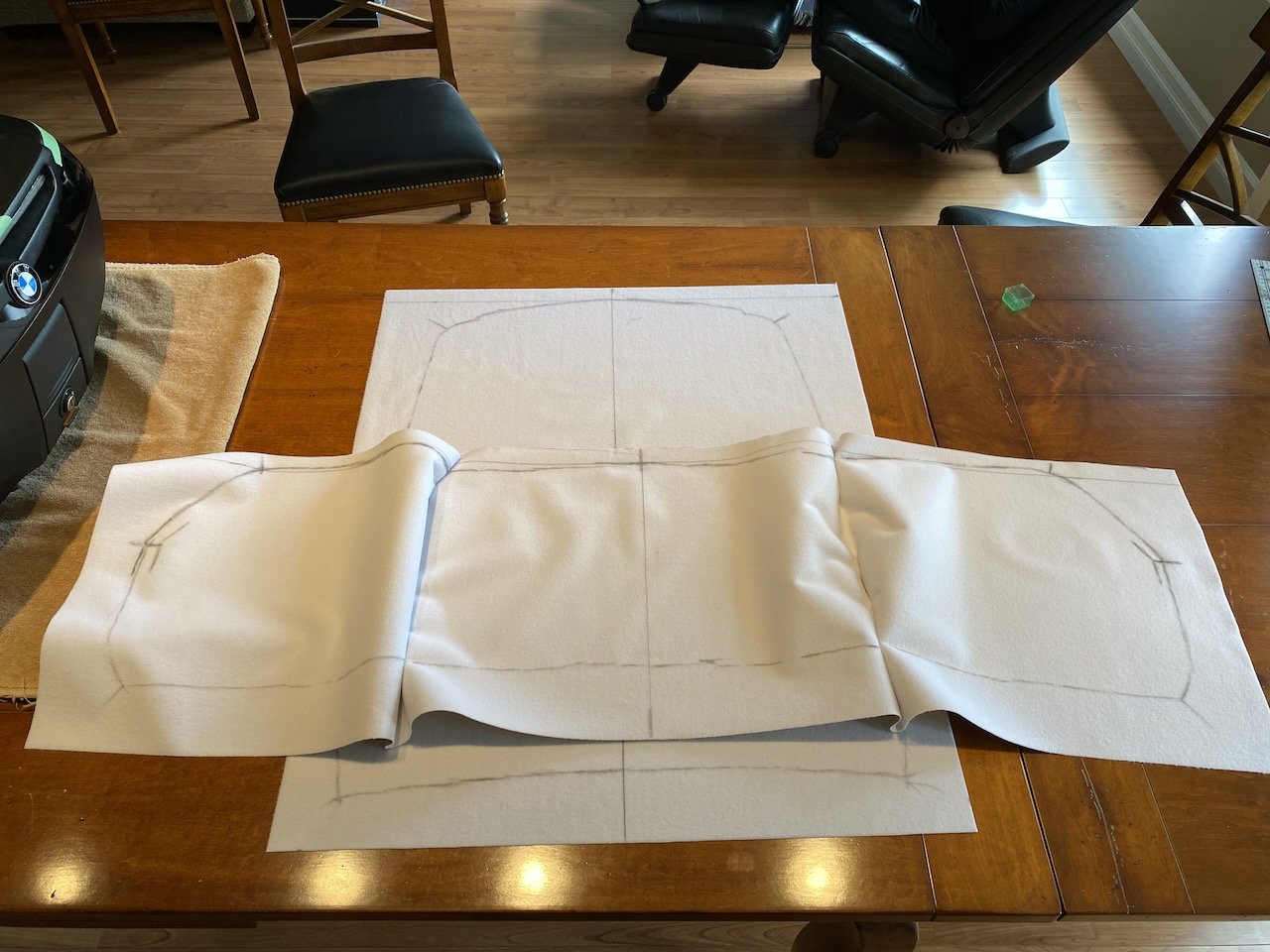

The second sleeve was a bit more complex. So the top box came off the bike and into the house where it could be manipulated easier on the dining room table.

The process was basically to wrap the fabric around the box and then start folding, cutting and pinning the fabric to the shape of the box. Since the shape was complex it required a lot of nip and tuck.

With the sleeves complete, the cover can now be installed without worry of scratching either the top box or the windshield.

Motorcycle Cover IMPROVED

With the added velcro straps and zipper, along with the velcro sewn to the “flaps” that are created when the bagginess of the cover is folded over onto itself, there is a big difference on how the cover lies on the bike. We’re very pleased with the outcome.